Description

Loading ...

Loading ...

Guidance mechanism. The RP screw jacks determine the angle of rotation of the satellite relative to the vertical axis and the inclination of the satellite dish in the horizontal axis in the front-rear directions.

Guidance mechanism. The RP screw jacks determine the angle of rotation of the satellite relative to the vertical axis and the inclination of the satellite dish in the horizontal axis in the front-rear directions.

High accuracy in setting the cylinder screw deflection enables very precise positioning of the antenna in this case.

Four-column lift. The height-adjustable worktop allows it to be loaded with elements when it is at the bottom (where it is potentially easier) and then allows the table to be raised to a height that is comfortable, for example, for processing the product or for assembling it.

Four-column lift. The height-adjustable worktop allows it to be loaded with elements when it is at the bottom (where it is potentially easier) and then allows the table to be raised to a height that is comfortable, for example, for processing the product or for assembling it.

Scissor lift. One actuator for each position allows you to change the height of the worktop. The simple construction and few moving parts allow you to duplicate the stations in a simple and economical way with possible mechanical synchronization.

Scissor lift. One actuator for each position allows you to change the height of the worktop. The simple construction and few moving parts allow you to duplicate the stations in a simple and economical way with possible mechanical synchronization.

Column lift. The MRP servo motor in SO version (rotary bolt) transfers loads to the mobile part of the lift. If the movable element is properly guided, the screw does not need to be supported at the bottom. The bearing of the actuator transfers loads to the stably mounted body.

Column lift. The MRP servo motor in SO version (rotary bolt) transfers loads to the mobile part of the lift. If the movable element is properly guided, the screw does not need to be supported at the bottom. The bearing of the actuator transfers loads to the stably mounted body.

Multistage scissor lift. An extensive version of the previously mentioned solution. It is possible to use several actuators to reduce their dimensions while maintaining load capacity. A double set of arms increases the lifting range of the table top.

Multistage scissor lift. An extensive version of the previously mentioned solution. It is possible to use several actuators to reduce their dimensions while maintaining load capacity. A double set of arms increases the lifting range of the table top.

Compact press. Replacement of hydraulic press with actuator / actuator set and housing. The simple and compact design allows easy service and the ability to quickly change gear in the transmission or replace any of the elements with a new one.

Compact press. Replacement of hydraulic press with actuator / actuator set and housing. The simple and compact design allows easy service and the ability to quickly change gear in the transmission or replace any of the elements with a new one.

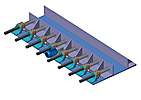

Horizontal press. Large-size device for stacking / joining / squeezing large elements such as concrete columns / steel pipes. It can also be used as a press for loose items such as waste paper / wood waste / rubbish. Mechanically coupled MRP screw jacks move the movable part to the fixed, unambiguously positioning the items that are between the press walls.

Horizontal press. Large-size device for stacking / joining / squeezing large elements such as concrete columns / steel pipes. It can also be used as a press for loose items such as waste paper / wood waste / rubbish. Mechanically coupled MRP screw jacks move the movable part to the fixed, unambiguously positioning the items that are between the press walls.

Positioning rolls in the paper or textile industry. MRP screw jacks determine the tension of the rolled element by pushing / moving the moving roller in the production process.

Positioning rolls in the paper or textile industry. MRP screw jacks determine the tension of the rolled element by pushing / moving the moving roller in the production process.

Mobile four-column ramp. Four MRP screw jacks at the top raise the approach for servicing purposes. Possible executions with an increased number of actuators to support a long vehicle, such as a locomotive.

Mobile four-column ramp. Four MRP screw jacks at the top raise the approach for servicing purposes. Possible executions with an increased number of actuators to support a long vehicle, such as a locomotive.

Conveyor belt. The MRP actuator allows you to change the path conveyed on the product belt to change its destination point. It is possible to make up-down and right-left adjustments.

Conveyor belt. The MRP actuator allows you to change the path conveyed on the product belt to change its destination point. It is possible to make up-down and right-left adjustments.

Bar. Device closing the flow of medium through the diameter or profile by guiding the closing element / flap up-down or front-rear.

Bar. Device closing the flow of medium through the diameter or profile by guiding the closing element / flap up-down or front-rear.