GENERAL INFORMATION ON Bevel GEARS

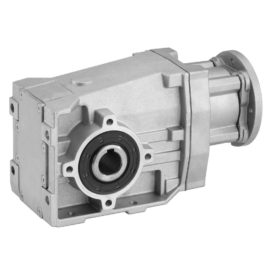

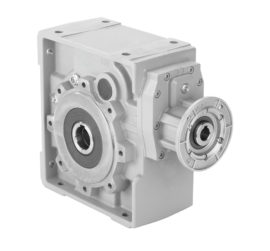

The gears of the HS series are helical-bevel gearmotors, also commonly called angular, due to the transmission of the drive at right angles.

The HS series of reducers is the perfect solution when we want high efficiency and durability of the gears. It is distinguished by a compact structure, durable body, a wide range of gear ratios, sizes and versions of mounts.

A wide range of sizes of geared motors allows you to choose the optimal drive from small aluminum ones transmitting 70Nm to large cast iron ones with a torque of 5000Nm.

The range of gear ratios we offer in one body is from 6 to 821. Larger ratios are obtained by combining two gears.

Bevel BOXES

We offer gearboxes in aluminum and cast iron housings, which are made by injection.

Aluminum bodies are vacuum impregnated, making them extremely tight and suitable for possible painting.

Cast iron casings are painted in a standard color from the RAL7046 palette

The internal ribbing of the bodies allows the transfer of high forces and torques. External ribbing perfectly dissipates heat, so the reducer does not overheat.

SCREW GEAR WHEELS IN Bevel GEARS

Thanks to helical (helical) teeth in the cylindrical stage and curved teeth in the conical (hypoid) stage, which are ground after hardening, the gear transmits greater loads than the classic gear with straight teeth and is additionally quiet. Thanks to the perfectly made teeth, the efficiency is up to 96%, which translates into energy savings.

Many manufacturing companies, in order to become a more environmentally friendly company and further reduce energy consumption, have requirements to replace helical-bevel gears with them, which have lower efficiency. For example, you can compare a worm gear and a helical-bevel gear with a gear ratio of 100. The worm gear has an efficiency of about 60% and a helical-bevel gear of 96%. It is easy to notice that in the case of continuous 3-shift work it is a significant saving.

ASSEMBLY OF Bevel GEARS

It is worth mentioning the four sizes of HS reducers:

- HS-423 and HS-424, with dimensions and mounting identical to the TM-110 transmission;

- HS-453 and HS-454, with dimensions and mounting identical to the TM-130 gearbox.

Thanks to this, the replacement of worm gears with highly efficient helical-bevel gears is very simple and does not require changes in the design.

For geared motors, we most often use alternating current electric motors flange mounted in the IEC standard. The transmission of torque can be by means of a clutch or classic - where the motor shaft is slidably mounted in the sleeve inside the gear. We also make adapters to connect servo (square) motors, hydraulic (oval), pneumatic and other motors after sending your drawings. For the adapters, we can use claw couplings that dampen vibrations and compensate for misalignment.

In the case of manual or belt or chain drive, we install a solid shaft instead of the standard motor connection. It is not a "glue" mounted shaft, which is the case with some manufacturers. It is a monolithic shaft with bearings and a pinion. So there is no possibility of ejecting it, which may be dangerous for a person or harmful to the machine.

Helical-bevel gear units can be an interchangeable mount for gears of other manufacturers. They are produced with the popular diameters of the output sleeve and the spacing of the mounting holes. Such interchangeability has been appreciated by companies providing maintenance services that need a quick replacement of reducers, and the manufacturer of the original drive offers several weeks of implementation. The gears are installed in our company overnight, and in the event of a breakdown, we can even make the gears on the spot. In addition, our gearbox in the same mounting can transfer a larger nominal torque than previously used, which is an excellent solution to avoid future failures and downtimes. Our gears are also easy to use in new devices. It is not necessary to change the mounting in the structure.

In the HS series, we can also make special mounting flanges according to the drawings sent, as well as single and double-sided output rollers. Where the gearbox is mounted on the shaft in the machine, torque transmission can be provided by using the version with an expansion / clamping sleeve. This design allows for quick disassembly of the drive in the event of service. In the case of mounting (hanging) on the machine shaft, we recommend dedicated reaction arms with a polyamide insert to take away the degree of freedom.

HIGH QUALITY OF BEARINGS AND SEALS IN Bevel gears

We use top class bearings to ensure quiet and trouble-free operation. The range of transmitted axial and radial loads on output and drive shafts is included in the catalog. In the case of projects where the transmission of higher loads is required from the gears, we can use reinforced bearings.

Our gears are equipped with high-class seals. Simmerings have two lips: the inner one prevents oil from escaping, and the outer one provides protection against dust. In case of high temperatures, we provide installed Viton seals with better thermal parameters.

We also use Viton seals in explosion-proof versions. We can adapt the gears and provide the required certificates for the gas explosion zone 1 (ATEX II2G) and 2 (ATEX II3G) and dust zone 21 (ATEX II2D) and 22 (ATEX II3D).

OIL CHOICE FOR CONICAL GEARS

In the case of food processing plants, where sanitary requirements are increased, we are able to flood the gear with cooking oil with appropriate certificates. Additionally, we can make the output shaft of stainless steel. If the requirements are at the highest level, we encourage you to familiarize yourself with the CGT series transmissions, typically designed for food and chemical plants.

Proper operation of the gearbox at low temperatures is ensured by the use of a special oil.

Our geared motors work all over the world. They gained their popularity due to failure-free operation, attractive price, quick delivery times and the availability of spare parts.